For industrial producers, achieving high-speed packaging without compromising product protection is essential. This is where the horizontal packaging machine plays a critical role in efficient flow wrapping—widely used for baked goods, الأطعمة المجمدة, and more.

At CHLB Group, we provide integrated horizontal flow wrapping solutions that help manufacturers optimize speed, stability, and scalability. In this guide, we explain how horizontal packaging machines work, compare key machine types and sealing methods, and highlight critical technical factors—from PLC/HMI controls to film compatibility such as PP and PE—to help you choose the right solution for your production line.

What is Flow Wrapping and Why It Matters?

Flow wrapping is a continuous horizontal packaging method where products are sealed in a flexible film to create a 3-side sealed pack. It is vital for industrial producers due to its ability to combine high-speed throughput with robust product protection, hygiene, and extended shelf life, making it ideal for items like baked goods and frozen foods.

Understanding Flow Wrapping: Process and Importance

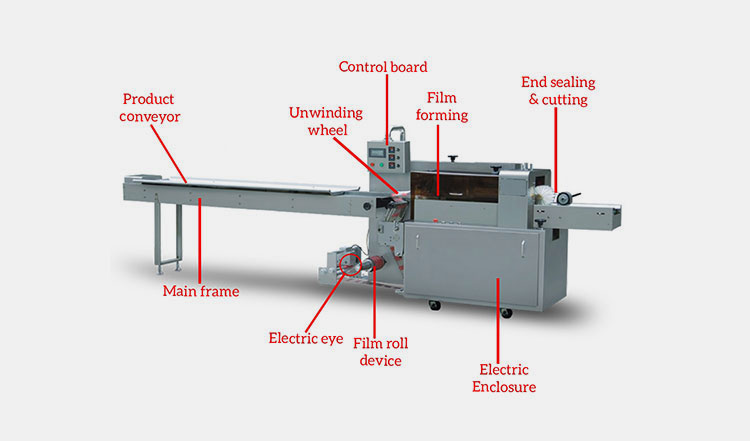

Flow wrapping is fundamentally a continuous horizontal form-fill-seal (HFFS) packaging process. Products are systematically introduced onto an in-feed conveyor, which then transports them to the wrapping station. Here, a flat web of flexible film is precisely wrapped around the product, forming a continuous tube. This tube is then sealed longitudinally, and subsequently cross-sealed and cut to create individual, 3-side sealed packages.

This method is crucial for industrial producers because it efficiently combines robust product protection, stringent hygiene standards, and extended shelf-life performance with high throughput and a low unit cost.

Consequently, it is widely adopted for packaging a diverse range of items including chocolates, snack bars, baked goods, بسكويت, frozen items, and other individual food portions where maintaining hygiene and ensuring precise portion control are paramount.

Key Technical Features and Performance Advantages

Flow wrapping machines are built for high-speed, high-precision production, combining advanced control and material flexibility:

- Flexible packaging options

Compatible with PE, PP, PET, and polyolefin films, with optional MAP/gas flushing for extended shelf life.

- High-speed performance

Up to 200–300 packs per minute, depending on the sealing jaw configuration.

- Intelligent control

PLC with touchscreen HMI, servo-driven motion, and photocell sensors for accurate sealing and registration.

- Waste and quality control

“No product–no bag” logic and precision heat sealing, with optional water-cooled jaws for heat-sensitive items.

What Are the Different Types of Flow Wrap?

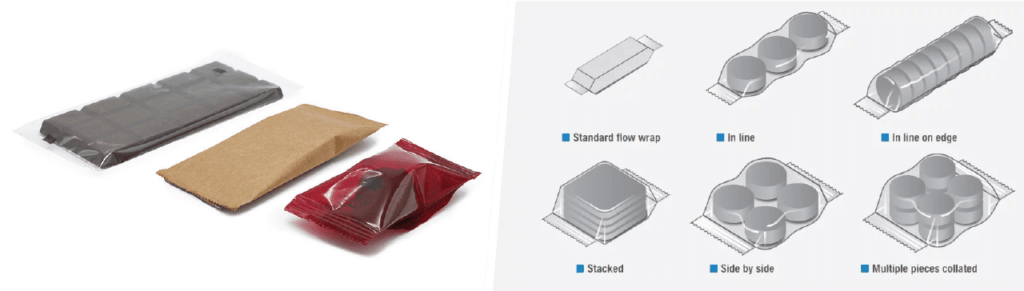

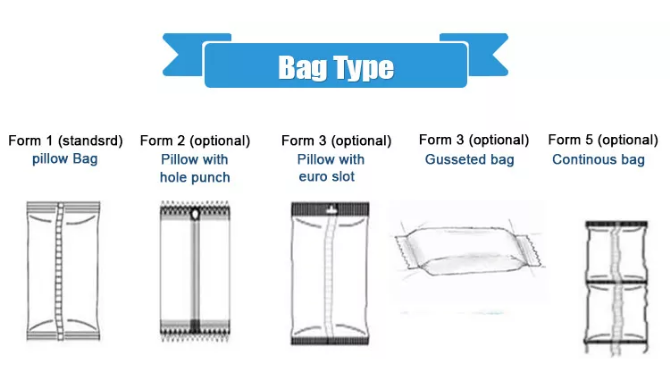

Flow wrap types are primarily distinguished by their sealing geometry (e.g., pillow-pack, inverted seal, 3-side, 4-side) and film path, alongside the specific material composition used. These configurations are chosen based on product characteristics, desired presentation, and required barrier properties, from high-speed bakery items to specialized medical devices.

Key Flow Wrap Configurations by Seal and Film Path

Pillow-pack (fin-seal) flow wrap: Features a back seam and two cross seals, typical for bars, bakery items, and frozen novelties, often using film-from-above conventional wrappers.

Inverted / back-seal flow wrappers: Film fed from below, creating a longitudinal seal on the top surface, ideal for delicate or sticky products needing clean top presentation.

3-side-seal horizontal wrappers: Create flat packs with three sealed sides from a single web, commonly used for small, flat items and portion sachets.

4-side-seal horizontal wrappers: Produce flat flexible packs sealed on all four sides, frequently used for medical devices, sliced meat, and cheese, offering enhanced barrier properties.

Specialized Film Materials for Performance and Application

Polypropylene (PP) family films (BOPP/CPP): Standard for snacks, candy, and many baked goods due to versatility in transparency, printability, and opacity.

Polyethylene (PE) family films (LDPE, LLDPE, HDPE): Used for bakery, pizza, and bread, with HDPE+EVA blends specifically engineered for frozen food and crackers requiring toughness and low-temperature performance.

Laminates / co-extrusions (e.g., PP/PE, PET/PE): Multi-layer structures designed to provide improved barrier properties, stiffness, or reliable sealing through contamination for demanding applications.

Flow Wrapping vs. Shrink Wrapping: What’s the Difference?

Process and Core Functionality

Flow wrapping: Utilizes a horizontal form-fill-seal (HFFS) process where film wraps and seals around products in a continuous motion, without requiring a heat tunnel.

Shrink wrapping: Involves heat-sensitive film (e.g., PVC, polyolefin, polyethylene) that shrinks tightly around products when exposed to heat from a tunnel or gun.

Flow wrapping is optimized for high-speed, continuous production of uniform single items such as snacks and bars.

Shrink wrapping is better suited for bundling multiple items, packaging irregular shapes (e.g., bottles, boxes), and providing stability.

Speed, Film Properties, and Finished Product Characteristics

Flow wrapping speed: Offers fast, continuous operation, making it ideal for high-volume production lines.

Shrink wrapping speed: Generally slower due to the required heat application and contraction process.

Flow wrapping finish: Creates a sleek ‘pillow-pack’ with an airtight seal, providing excellent moisture and contaminant protection.

Shrink wrapping finish: Results in a tight, form-fitting package that is tamper-evident and offers puncture/tear resistance.

Common flow wrapping films: Polypropylene or laminated films are typically used.

Common shrink wrapping films: Polyolefin is most common for a smooth texture, available in gauges like 45, 55, 60, 75, و 100 gauge.

Engineering distinction: Flow wrapping uses fin seals for form-fit without thermal shrinkage; shrink wrapping relies on thermal contraction, typically achieving a 40-60% shrink rate.

Intelligent Packaging Machinery for Peak Productivity

How to Choose the Right Flow Wrapping Machine for Your Business

Choosing the right flow wrapper involves evaluating operational needs like product dimensions, required speed, and film compatibility. Technical considerations such as machine construction (e.g., stainless steel for hygiene), drive systems (full-servo), and control features (PLC, HMI, recipe storage) are crucial for efficiency, sanitation, and long-term reliability in diverse production environments.

| Feature | Key Specification | Details/Impact |

|---|---|---|

| Speed Range | `30–120 packs/min` (compact); `250–350+ packs/min` (high-speed); `2 × 700 packs/min` (dual-lane) | Determines production capacity for various operational scales. |

| Product Dimensions | e.g., `bag length 130–400 mm`, `width 30–140 mm`, `height 35–70 mm` (compact); up to `610 mm` film width, `270 mm` product width, `100 mm` product height (larger) | Governs product size compatibility and machine forming capabilities. |

| Film Compatibility | `OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC` multilayer films | Ensures proper barrier needs, product protection, and sealing methods. |

| Construction Material | `Stainless steel frame` vs. `Painted carbon steel` | Critical for hygiene, durability, and suitability for washdown environments (food-grade). |

| Drive/Control System | `Full-servo drives` (3+ motors); `Industrial PC / PLC` (e.g., Allen‑Bradley, Mitsubishi); `HMI`, `Recipe storage` (50–100 formats) | Ensures operational efficiency, precision, quick changeovers, and diagnostics. |

| Sanitation Features | `Cantilever construction`, `Washdown-capable designs` | Facilitates ease of cleaning, critical for hygiene and allergen management. |

| Footprint/Power | `4.8–5.0 m` length, `~1.0 m` depth (compact, `<5 m²`); `3.7–7.5 kW`, `220–230 V` | Defines space requirements and energy consumption. |

Assessing Your Operational Needs: منتج, Throughput, and Film Compatibility

Determine required throughput: from `30–120 packs/min` for compact machines up to `250–350+ packs/min` for high-speed, or even `2 × 700 packs/min` for dual-lane systems.

Evaluate product dimensions and flexibility: e.g., `bag length 130–400 mm`, `width 30–140 mm`, `height 35–70 mm` for compact units, up to `610 mm` film width for larger products (`270 mm` product width, `100 mm` product height).

Confirm film material compatibility: common types include `OPP, OPP/CPP, PT/PE, KOP/CPP, PVDC/PVC` multilayer films, ensuring matching barrier needs and sealing methods.

Key Technical Specifications and Hygienic Design Requirements

Prioritize construction materials: `stainless steel frame construction` for food-grade designs, especially for washdown environments, versus `painted carbon steel`.

Examine drive and control systems: `full-servo drives` with `3+ servo motors`, `industrial PC / PLC control` (e.g., Allen‑Bradley, Mitsubishi), `HMI touch screen`, and `recipe storage (50–100 formats)` for operational efficiency.

Consider sanitation features: `cantilever construction` for access and `washdown-capable designs` compatible with hot water/chemical cleaning, crucial for hygiene and allergen management.

Note machine footprint and power: typical compact units around `4.8–5.0 m` length and `~1.0 m` depth (under `5 m²` footprint), with power requirements of `3.7–7.5 kW`, `220–230 V`.

Final Thoughts

Horizontal flow wrapping machines are a cornerstone of modern industrial packaging, delivering efficient, continuous, and hygienic protection across food, medical, and consumer goods applications. Advanced servo control, intelligent “no product–no bag” logic, and wide film compatibility ensure high-speed output, extended shelf life, and consistent seal integrity—from standard pillow packs to specialized four-side seals.

Choosing the right horizontal flow wrapper is a strategic investment that directly affects efficiency, cost control, and market competitiveness. At CHLB Group, we work closely with manufacturers to assess production speed, product dimensions, film characteristics, and hygiene requirements—helping you select a solution that maximizes performance and long-term value. Contact our packaging specialists to explore a flow wrapping system tailored to your production goals.

Frequently Asked Questions

What Is a Horizontal Flow Wrap Machine?

A horizontal flow wrap machine (horizontal flow wrapper, HFFS) is a continuous‑motion form‑fill‑seal packaging machine where products are fed horizontally on an infeed conveyor, enclosed in a tube of flexible film, then fin‑sealed along the length and end‑sealed/cut into individual packs, typically at speeds from about 30 up to 200+ packs per minute for bakery and frozen foods. These machines usually handle products up to roughly 60–120 mm in height, film rolls around 320 mm max diameter, and web widths roughly 370–650 mm, using heat‑sealable films such as OPP/CPP, PT/PE, PVDC laminates to produce pillow or flow‑wrap packs.

What Material Is Flow Wrap Packaging Made Of?

Flow wrap packaging for bakery and frozen foods is typically made from polyolefin-based films, most commonly polypropylene (PP) and polyethylene (PE), often as oriented polypropylene (OPP) or co-extruded/laminated structures like PET/PE or METPET/PE, and increasingly barrier-coated paper grades designed for horizontal flow-wrappers. These films are supplied in thin gauges (commonly in the 20–80 µm range for HFFS food applications, per typical converter specs) and engineered for high sealability and machinability on horizontal flow-wrapping lines.

How Does a Flow Wrap Machine Work?

A flow wrap machine feeds products via an infeed conveyor into a continuous tube of film formed by a folding box, seals the film longitudinally with fin seals using 3 pairs of rollers, and then applies rotary or box motion cross-sealing jaws to create hermetic end seals while cutting packages at speeds up to 100 packs/min for standard models or 2 x 700 packs/min for high-output twins, fully servo-controlled with stainless steel construction for bakery products up to 280 mm wide and 180 mm high.

What Type of Plastic Is Used in Flow Wrap?

Flow wrap packaging commonly uses polyethylene (PE) films, including low-density (LDPE), linear low-density (LLDPE), and high-density (HDPE) variants, and polypropylene (PP) films for their sealing properties, flexibility, clarity, and durability in food applications like bakery and frozen goods.