Navigating the world of pouch packaging machines can feel complex, especially when your production goals demand both efficiency and standout product presentation.

This article delves into the diverse world of pouch packaging machines, a critical sector within the global flexible packaging market, which is projected to reach USD 242.85 billion by 2033. We will compare stand-up and sachet solutions, analyze performance differences like high-speed rotary machines capable of producing 30 to 150 bags per minute, and discuss how to choose the right technology for your specific production needs. Let’s dive in together!

The Rise of Flexible Pouch Packaging in Retail

Flexible pouch packaging has grown in retail due to its convenience, cost savings, lightweight design for e-commerce, and strong market expansion, especially in food, beverages, and consumer goods.

Fundamental Drivers of Pouch Packaging Adoption

Pouch packaging offers significant convenience for consumers, enhancing user experience.

Cost savings are achieved through reduced material use and optimized logistics, benefiting food packaging machine manufacturers.

The lightweight design of pouches is crucial for efficient e-commerce shipping, directly lowering transportation costs.

The market demonstrates robust growth, particularly within the food, beverage, and consumer goods sectors.

Pouches, especially stand-up varieties, enhance shelf presence, captivating consumer attention in retail environments.

Logistics costs see a substantial reduction; pouches are up to 70% lighter than rigid packaging alternatives.

Features like resealable closures and retort technology contribute to product shelf stability and provide consumer convenience.

Premade Pouch vs. Form-Fill-Seal (FFS) समाधान

Premade pouch machines use pre-formed pouches for high-end aesthetics and diverse designs, suitable for premium products. They have higher costs for machines and materials, and moderate speeds. Form-fill-seal (FFS) systems create pouches from roll stock on-site, offering lower costs and higher speeds for large-volume, simpler designs. The best choice balances cost, speed, packaging quality, and desired flexibility.

| Aspect | Premade Pouch Machines | Form-Fill-Seal (FFS) Machines |

|---|---|---|

| Cost | Higher machine price, premade pouches cost more (e.g., 30% > roll stock); greater initial investment[1][2][5][8] | Lower machine and material costs; economical for pouches and equipment[1][2][3][5] |

| Speed | Moderate; slower than FFS, limited by filling/weighing[1][3] | Higher volumes and faster speeds, especially vertical FFS for lightweight products[1][3][4] |

| Packaging Quality | Better appearance, neater edges, more styles (stand-up, zipper); stands out for branding[1][2][6] | Simpler designs; good for pillow/gusset but less premium look[1][2][6] |

| Flexibility | High variety of pouch types/sizes; handles powders, liquids, solids[3][4] | Adjustable sizes on-site; high filling flexibility but fewer complex styles[3][4][5] |

| Waste & Efficiency | 12-15% trim waste; 82-87% material utilization; more storage (40% more space), 12-month shelf life[5] | Near-zero waste; 98.6% utilization; 20% less film waste; compact roll storage[5] |

| Best For | High-end branding, smaller batches, custom features[2][3][5] | High-volume, cost-sensitive, simple pouches (e.g., powders, single-serve)[3][5] |

Premade Pouch Packaging: Design and Versatility

Premade pouch machines use pre-formed pouches, allowing for superior aesthetics and varied bag styles (e.g., stand-up, zipper, spout).

They offer extensive flexibility in design, making them ideal for strong branding and premium product presentation.

Initial machine costs and material expenses for premade pouches are typically higher, with pouches costing approximately 30% more than roll stock film.

Production speeds are moderate, making them suitable for specialized products or smaller batches where appearance is paramount.

Form-Fill-Seal (FFS) समाधान: Efficiency and Scale

Form-fill-seal (FFS) machines, particularly vertical FFS (VFFS), form pouches on-site from roll stock film.

These systems offer lower machine and material costs, providing an economical choice for high-volume production.

FFS machines achieve higher speeds, especially for simpler bag styles like pillow or gusset pouches, minimizing material waste.

While highly efficient for large runs, FFS typically offers less design flexibility and produces simpler pouch appearances compared to premade options.

Strategic Selection: Performance and Application

The choice between premade pouch and FFS solutions depends on key factors like cost, speed, packaging quality, and flexibility.

Premade pouches excel for high-end branding, custom features, and diverse styles, often chosen for smaller, premium batches.

FFS is the preferred method for high-volume, cost-sensitive operations producing simpler pouches, demonstrating near-zero material waste.

Companies need to weigh initial investment against operational efficiency and desired product presentation to determine the optimal packaging technology for their needs in 2026.

Next-Gen Packaging for Peak Performance

Sachet vs Stick Packs

Key Design and Structural Differences

Sachets are flat, pillow-like pouches sealed on four sides, typically measuring 40-80mm wide by 50-100mm long, ideal for volumes from 5-20ml.

Stick packs are narrow, elongated tubes with three-sided seals plus a vertical back seal, generally 15-40mm wide by 80-200mm long, suitable for 1-15ml volumes.

Sachets offer a wider dispensing area (40-80mm) and provide 30-40% more printable area for branding compared to stick packs.

Stick pack seals are typically narrower (3-6mm) than sachet seals (5-10mm).

Material Efficiency and Optimal Applications

Stick packs use 15-25% less material, reducing waste and contributing to lower production costs ($25-32 per 1000 units compared to $30-40 for sachets).

Sachets work well for viscous products like creams, sauces, and multi-dose applications, enabling 40-60% faster dispensing for items such as ketchup or mayonnaise.

Stick packs are optimal for fine powders and granules, including supplements and coffee, showing 40% fewer spills and a significantly lower spillage rate (3% vs. 12% for sachets).

From a production standpoint, stick pack machines enable higher speeds and offer 15-20% shipping savings due to compact storage, making them efficient for high-volume needs.

High-Speed Rotary Pouch Machines for Large Production

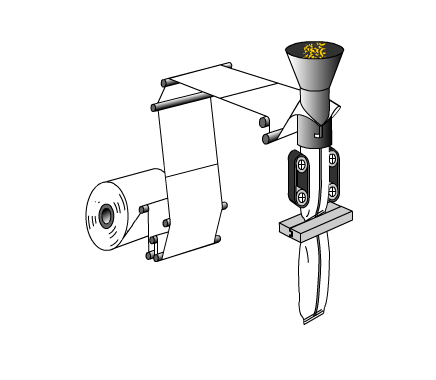

High-speed rotary pouch machines are crucial for large-scale production, automating feeding, filling, and sealing. They maximize output and ensure consistent quality across various products. Operating at speeds from 30 to 150 bags per minute, with some systems reaching 120 pouches per minute in duplex mode, these machines handle pouch widths from 60 mm to 285 mm and lengths up to 500 mm. Filling capacities range from 10 grams to 1500 grams or 5 pounds. Key features often include multi-station rotary systems (e.g., 8-station, 12-station), integrated vacuuming capabilities, and PLC controls for precise, continuous operation.

Driving Efficiency in Large-Scale Pouch Packaging for 2026

High-speed rotary pouch machines are essential for large-scale production lines that need automated feeding, filling, and sealing processes.

They maximize output and ensure consistent quality, handling diverse products ranging from food to industrial goods effectively.

These systems integrate advanced automation, making them suitable for continuous, high-throughput operations globally.

Key Operational Metrics and Machine Capabilities

Speeds typically range from 30 to 150 bags per minute, with some systems achieving up to 120 pouches per minute in duplex mode for maximum efficiency.

Machines accommodate a wide range of pouch sizes; widths typically span 60 mm to 285 mm and lengths can go up to 500 mm.

Filling capacities vary significantly, from 10 grams up to 1500 grams or 5 pounds, catering to diverse product types like powders, granules, and liquids.

Advanced features include multi-station rotary systems (e.g., 8-station, 12-station configurations), integrated vacuuming capabilities, and PLC control systems like Siemens for precise operation.

Pouch Shape Customization and Branding Impact

Pouch shape customization in packaging machines allows for adjusting parameters like width, length, forming area, and sealing types. This produces varied shapes such as 3/4-side seal, stand-up, zipper, or center-seal pouches, with dimensions ranging from a minimum of 30 mm width/length to a maximum of 508 mm width and 650 mm length. Precise control over these customizations improves branding, creating high-quality seals, consistent shapes for logo placement, and efficient production speeds (10–200 pouches/min). This also enhances visual appeal, shelf differentiation, and consumer recognition for flexible packaging users.

Precision in Pouch Shape and Size

Pouch customization provides flexibility to adjust parameters like width, length, forming area, and sealing types, creating varied pouch shapes.

Machines can produce 3/4-side seal, stand-up, zipper, and center-seal pouches.

Dimension options include widths and lengths from 30 mm up to 508 mm width and 650 mm length.

Specific machine models support web widths up to 508 mm and seal repeats up to 609 mm, handling many different formats.

Strategic Impact on Brand Presentation

Customization strengthens branding through exact control, leading to high-quality seals and consistent shapes for logo placement.

Tailoring pouch designs improves visual appeal, shelf differentiation, and consumer recognition.

Consistent pouch shapes enable sharp printing and tamper-evident seals, keeping defects below 2.5% in controlled production environments.

High-speed production, up to 200 pouches per minute, supports scalable branded runs with efficient operation.

Machines precisely fill products like coffee, powders, and granules (5–3500 g), which boosts perceived product quality.

Touchscreen HMIs and servo drives on machines simplify shape adjustments, helping flexible packaging users.

Factors to Consider When Choosing a Pouch Packing Machine

Production Capacity

Evaluate the production capacity of the machine to ensure it can handle your output requirements. Consider both current and future production needs to avoid bottlenecks as your business grows.

Packaging Material Compatibility

Ensure the machine is compatible with the packaging materials you intend to use. Different products may require different types of pouches, and the machine should be versatile enough to handle them all.

Machine Footprint and Layout

Consider the physical footprint of the machine and how it will fit into your production layout. Space constraints and workflow integration are critical factors to ensure smooth operation and maintenance.

Automation Level

Assess the level of automation the machine offers. Higher automation levels can significantly reduce labor costs and increase efficiency, but they may also come with higher upfront costs. Balance these factors based on your operational priorities and budget.

Final Thoughts

Making the right packaging machinery choice involves carefully considering production scale, product characteristics, branding goals, and budget. Whether a business needs high-speed automation with rotary systems or custom pouch shapes for market differentiation, selecting the appropriate technology ensures operational efficiency. Understanding these options helps companies optimize their packaging strategies and maintain strong consumer appeal in today’s competitive market.

As the packaging industry continues to evolve, investing in a premade pouch packing machine from a reliable food packaging manufacturer can provide a competitive edge, driving growth and success in a dynamic market.