業界 4.0

Your Reliable Partner for Precision, Proven Production

25 years of experience combined with intelligence-driven precise manufacturing set your packing line apart when it comes to automation. Our Industry 4.0-enabled facility redefines high throughput, precision, and operational excellence in packaging solutions, solving your worries and freeing up your time to focus on fine-tuning your business.

80% Automation

High level of automation in spare parts production, laser cutting and CNC centers.

100% In-house

Complete packaging lines are created from scratch within our factory.

100% Inspection

Every line, without exception, is completely inspected before shipment.

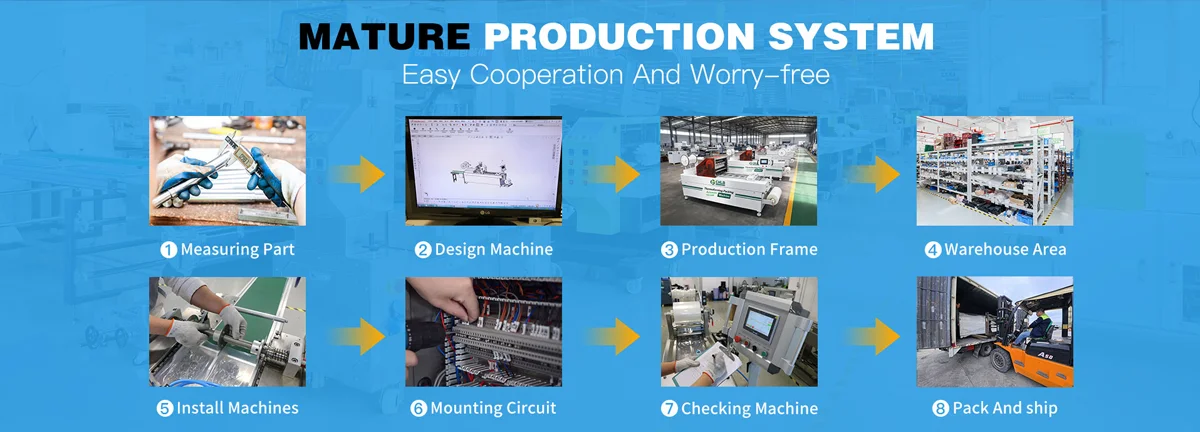

Optimized Production for Consistent Packaging Performance

Material Selection

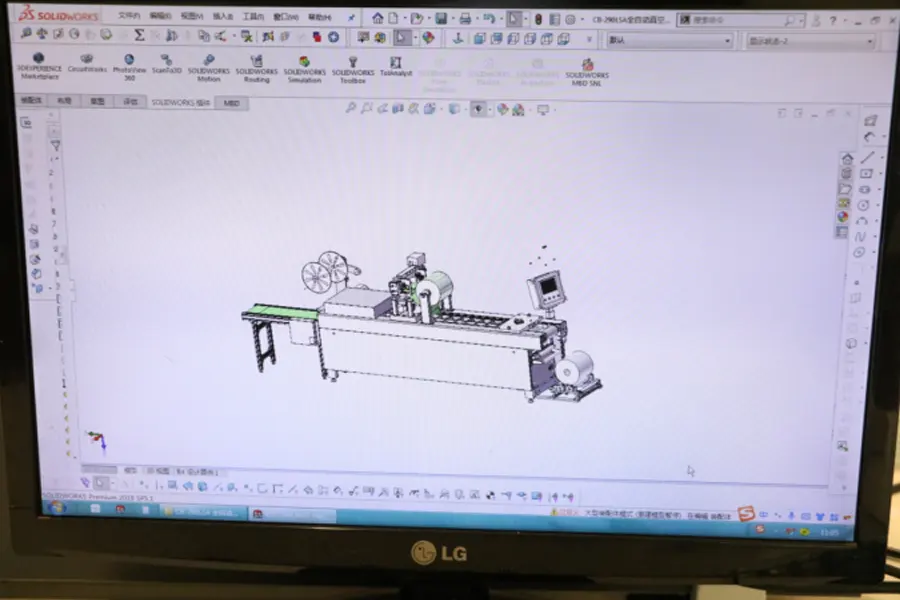

CAD Drawing

CNC Processing

Component QC

Assembly

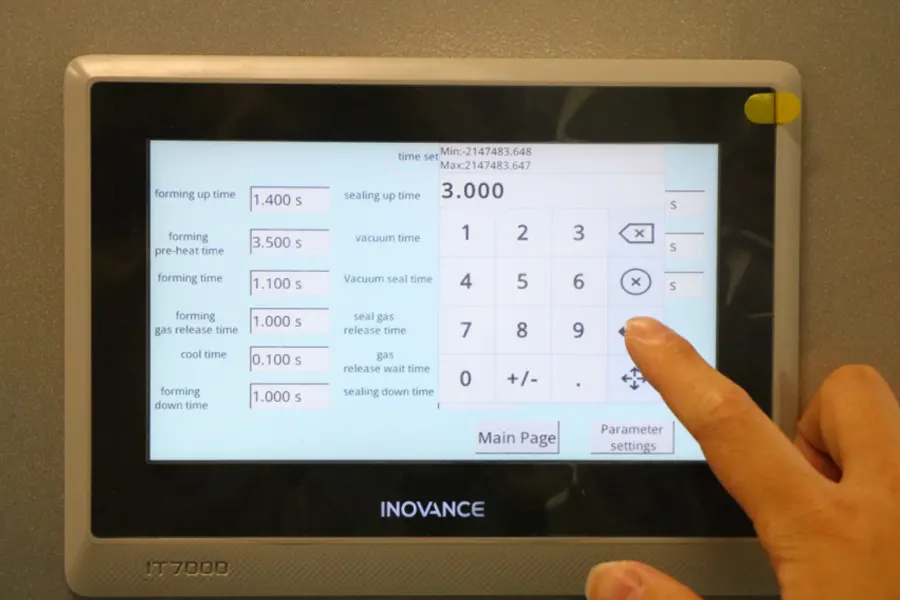

Commissioning

Expand Your Business without Compromising Quality

Our stringent inspection standards check and debug every fragile error on finished lines before shipping, reducing the risks and costs of future maintenance.

Incoming Material Inspection

Every stainless steel and aluminum must be thoroughly tested prior to mass manufacturing.

Electronic Parts Quality Check

Inspect for visual defects, perform power-ups to test operation as well as conduct signal tuning.

Mechanical Component Quality Check

Following GMP standards to perform electrical, voltage and compatibility tests.

Finished Product Inspection

Conducts an empty running test to check weighing accuracy, sealing, and overall line stability of package deliverables.

Final Delivery Inspection

Our engineers ensure all modules of each packing line are in working order before shipment, along with detailed technical documentation.

Solid Partnership Beyond Machinery

Succeed with CHLB’s 6S Excellence

Sort

Each production material is separated and categorized, eliminating 99% of the risk of material contamination.

Set in Order

Place production tools and components precisely and correctly, reducing time, increasing productivity.

Shine

Daily maintenance of factory hygiene with regular audits and reports to create a healthy and safe production environment.

Standardize

Standardization and uniformity of manufacturing instructions and rules in the plant provide a clear path to profitability.

Sustain

Cultivate employees on a regular basis to form good work habits and participate in 6S management in the long run.

Safety

Anticipate and map out risk areas, guaranteeing that all production is built on safety foundation.