In the fiercely competitive snack industry, ensuring your chips and nuts reach consumers in perfect condition, with maximum freshness and minimal waste, is paramount. As we look towards 2026, the right snack packaging machine isn’t just about speed; it’s about a strategic investment that preserves product integrity, extends shelf life, and drives profitability in an increasingly demanding market.

This complete buying guide cuts through the complexity, offering B2B buyers a clear roadmap to selecting the optimal snack packaging machine. We’ll delve into the nuances of Vertical Form-Fill-Seal (VFFS), Horizontal Flow-Wrap (HFFS), and premade pouch systems, detailing their specific applications and performance metrics. Let’s dive in!

Snack Packaging Machine Types

Snack packaging machines are primarily categorized into Vertical Form-Fill-Seal (VFFS), Horizontal Flow-Wrap (HFFS), Cup/Tray/Tub fillers, and Pre-made Pouch Packers. Each type is designed for specific pack formats, product characteristics, and production speeds, ensuring optimal efficiency and presentation for various snack products.

Overview of Primary Snack Packaging Technologies

Industrial snack packaging is dominated by a core set of machine architectures: Vertical Form-Fill-Seal (VFFS), Horizontal Flow-Wrap (HFFS), cup/tray fillers, and pre-made pouch packers.

Each machine type is specifically matched to particular pack formats, product characteristics, and desired throughput bands.

VFFS machines are the workhorse for chips and extruded snacks, forming bags vertically from a film roll and typically using multihead weighers.

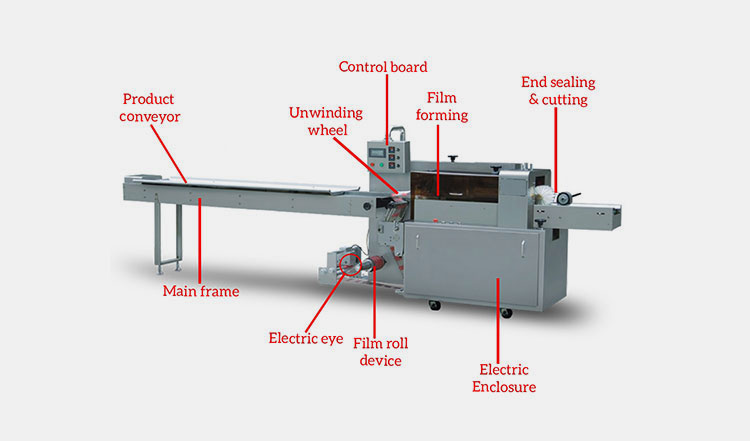

HFFS/flow-wrappers are preferred for bar-type snacks, confectionery, and countable items, creating horizontal pillow-type packs.

Cup/tray/tub filling lines are utilized for rigid or semi-rigid packaging, such as 1–8 oz cups for nuts, trail mix, or extruded snacks.

Pre-made pouch packers handle stand-up pouches, often with features like zippers, catering to premium snack products.

Key Specifications and Application Considerations

VFFS machines for chips often operate at 40–120 packs/min, handle film widths of 100–450 mm, and produce pillow-type, center seal, or standing bags.

VFFS filling technologies include multihead combination weighers, volumetric cup fillers, and auger fillers for granules/flaky snacks.

HFFS systems produce pillow-type flow-packs and are typically conveyor-fed for individual pieces or multipacks of items like chip bars.

Cup/tray/tub fillers accommodate portion ranges from 1–8 oz for single-serve to bulk packs, sealing containers with foil/film lids.

Pre-made pouch packers operate at 5–80 bags/min, supporting bag sizes from L 50–300 mm, W 60–200 mm, often for premium products requiring zippers or spouts.

Common features across types include PLC control, servo film transport, AC drives, power requirements of 1–3.5 kW, and compressed air in the 3–6 CFM at 6 bar range for pneumatic functions.

How They Work

Snack packaging machines primarily use vertical form-fill-seal (VFFS) bagmakers integrated with multihead weighers. Flexible film is formed into bags, filled with precisely portioned snacks, and sealed at high speeds. Advanced PLC controls, servo drives, and hygienic stainless steel construction ensure efficiency and accuracy.

Integrated Vertical Form-Fill-Seal and Multihead Weighing

Snack packaging systems are typically built around a Vertical Form-Fill-Seal (VFFS) bagmaker fed by a multihead combination weigher.

The process starts with a roll of flexible packaging film (e.g., OPP or PET/PE laminate) around 480–970 mm wide, pulled downward by servo-driven belts.

Film is shaped into a tube around a forming collar, then sealed longitudinally, followed by PLC-controlled horizontal sealing jaws creating the top and bottom seals.

Upstream, a multihead weigher (e.g., 10–14 heads) precisely portions snacks into buckets, delivering target weights at up to 120 weighments/min through the forming tube into the bag.

Technical Specifications and Advanced Control Systems

Machines handle film rolls with diameters up to 1000 mm, producing bag formats such as pillow, gusseted “English fold,” and flat-bottom bags.

Speed capabilities reach up to 100 bags/min for VFFS systems and 180–350 pcs/min for multi-lane stick-pack or sachet machines.

Control is PLC-based (e.g., Siemens, Omron) with servo-driven film pulling belts and sealing jaws, ensuring accurate bag length and consistent operation.

Construction materials include AISI 304 stainless steel for frames and AISI 316 for direct product contact parts, often with IP55-rated guards for hygiene.

Typical power requirements are ~10–12.5 kW (3-phase 380 V), with compressed air at 6 bar for actuators, consuming 20–450 L/min.

Unlock Peak Efficiency with CHLB Packaging Machinery

VFFS Solutions for Fragile Chips and Crisps

VFFS solutions for fragile chips and crisps feature multihead/linear weighers and servo-driven sealing on robust stainless-steel frames, ensuring gentle handling. They achieve speeds up to 150 bags/min, accommodating bag sizes from 80x80mm up to 800x500mm, and are compatible with various snack film laminates (40-120 µm thick).

Key Engineering for Product Integrity

Integrated multihead or linear weighers for gentle and accurate dosing, minimizing product breakage.

Servo-driven sealing jaws provide precise control over pressure and dwell time, crucial for fragile products.

Robust stainless steel frames ensure hygienic operation and stability for high-speed, controlled motion.

Self-centering pull belts and optimized forming collars prevent product damage during film handling and bag formation.

Performance Metrics and Material Compatibility

Packaging rates reach up to 100–150 bags per minute for light, free-flowing products like chips.

Supports a wide bag size range from 80 × 80 mm (minimum) up to 800 mm (L) × 500 mm (W) for various pack sizes.

Compatible with common snack film laminates including OPP/CPP, OPP/PE, PET/PE, and PE structures.

Designed for film thicknesses typically ranging from 0.04–0.12 mm (40–120 µm), accommodating standard barrier films.

Operates efficiently with 220 V, 3-phase, 50–60 Hz power and requires 90–120 PSI compressed air at ~20 CFM.

2026 Features & Trends

By 2026, snack packaging machines will be defined by accelerated automation, deep integration of sustainability, and advanced efficiency features. Fully automatic FFS and VFFS systems will dominate, driven by market growth, demanding high throughput while adopting smart technologies like IoT and predictive maintenance to reduce downtime and support eco-friendly materials.

Automation Acceleration and Sustainability Integration

Dominance of fully automatic Form-Fill-Seal (FFS) and Vertical Form-Fill-Seal (VFFS) systems, comprising approximately one-third of installations.

Profound integration of sustainability, with increased compatibility for mono-materials, compostable films, and physics-focused upgrades to minimize scrap.

High throughput capabilities are designed to meet growing snack demands, addressing e-commerce and enhanced hygiene requirements.

Snack Packaging Machine Comparison

Snack packaging machines are compared across three main types: VFFS, HFFS/flow wrappers, and premade pouch systems. Each excels in different areas, with VFFS offering versatility, HFFS speed for small packs, and premade pouch systems for premium formats, all varying in throughput, footprint, and film handling capabilities.

| Machine Type | Key Applications / Features | Performance Metrics |

|---|---|---|

| VFFS (Vertical Form-Fill-Seal) | Best for free-flowing snacks (chips, nuts, granules); forms bags vertically; supports advanced mono-material recyclable films. | Throughput: 30–300 bags/min (typical), up to 600 bags/min (advanced). Footprint: ~1.5 m (W) × 2 m (H). Energy: 2.5 kW (entry) to 8–15 kW (high-speed). Accuracy: ±0.1 g (with multihead weigher). |

| HFFS (Horizontal Form-Fill-Seal) / Flow Wrapper | Ideal for single-serve items, bars, biscuits, small snack packs; wraps horizontally. | Throughput: Up to 400 units/min, some up to 800 bags/min (high-speed). Footprint: ~3 m (W) × 7 m (L). |

| Premade Pouch / Stand-Up Pouch Systems | Premium snacks, pet food; uses pre-formed pouches; features like zippers, spouts, nitrogen flushing. | Throughput: 80–150 pouches/min. Changeover: ~15–20 min. Film Comp.: PET/PE, PET/AL/PE, BOPP/CPP, Nylon-based films. |

Core Machine Types and Their Applications

VFFS (Vertical Form-Fill-Seal) baggers: Best for free-flowing snacks like chips, nuts, and granules, forming bags from a roll of film vertically.

HFFS (Horizontal Form-Fill-Seal) / flow wrappers: Ideal for single-serve items, bars, biscuits, and small snack packs, wrapping horizontally.

Premade-pouch / stand-up pouch systems: Suited for premium snacks, pet food, and products requiring advanced features like zippers or spouts, using pre-formed pouches.

Performance Metrics and Operational Considerations

Footprint: VFFS approx. 1.5 m (W) × 2 m (H); HFFS approx. 3 m (W) × 7 m (L), requiring more floor space.

Energy Consumption: Standard VFFS 5–10 kW, high-speed models 8–15 kW.

Film Compatibility: Standard thermoplastic laminates; advanced VFFS supports mono-material recyclable films; pouch systems use PET/PE, PET/AL/PE, BOPP/CPP, Nylon-based films.

Choosing the Right Snack Packaging Machine Supplier

Selecting the ideal snack packaging machine involves matching production throughput, bag format flexibility, and utility requirements to operational needs, while ensuring compliance with stringent safety and hygiene standards like ANSI/PMMI B155.1-2023, BS EN 415-3, HACCP, and FDA regulations for food contact.

| Specification | Value/Range | Details |

|---|---|---|

| Typical VFFS Speed | 5–80 bags/min | For pillow or stand-up bags |

| Bag Size Capability (single lane) | L: 50–300 mm, W: 60–200 mm | Max film web width 420 mm |

| Film Thickness Range | 40–80 µm | Heat-sealable laminate |

| Filling Volume Range | 150–1500 mL | Standard VFFS system |

| Air Consumption (Typical) | ~200 L/min at 7 bar | For mid-size snack bagger |

| Electrical Load | ~2.5 kW, 220 V | 50–60 Hz |

| Machine Footprint (single lane) | 1400 × 970 × 1600 mm | Approx. 450 kg |

| High-Speed Lines (VFFS+Multi-head) | 60–80 pouches/min | Chips-type snacks; Film W: 100–450 mm, L: 100–250 mm |

| Higher Capacity Ranges | 10 g to 10 kg fill | Pouch L: up to 600 mm, Film W: up to 900 mm |

| Air Consumption (Alt. Spec) | ~3.4 CFM at 6 bar | For VFFS up to 1 kg |

| Weigher Material/Protection | Stainless Steel | IP65 for hygienic washdown |

| Safety Standard | ANSI/PMMI B155.1-2023 | Packaging machinery safety |

| Safety Standard | BS EN 415-3:2000 | Form, fill & seal machines |

| Hygiene/Food Safety | HACCP, FDA | Mandatory for food packaging lines |

Final Thoughts

The snack packaging machine landscape in 2026 is shaped by the convergence of efficiency, product protection, and rising sustainability requirements. Vertical Form-Fill-Seal (VFFS) systems paired with high-accuracy multihead weighers remain the industry standard for chips and nuts, achieving speeds of up to 200 bags per minute while preserving product integrity.

For buyers, choosing the right snack packaging machine is a long-term strategic decision that goes beyond today’s output targets. It requires future-ready equipment that supports tool-less changeovers, multiple SKUs, and rapid market adaptation. At CHLB Group, we help manufacturers evaluate and implement scalable snack packaging solutions that align with both current production demands and long-term growth. Connect with our team to explore the right system for your 2026 packaging strategy.

Frequently Asked Questions

What’s the difference between VFFS and multi-head weigher machines for snack packaging?

In snack packaging, a VFFS (Vertical Form Fill Seal) machine is the bagmaker that forms film into a vertical tube, fills it, and seals it, while a multi‑head weigher (MHW) is a separate weighing system that sits above the VFFS to dose snacks to a very tight weight tolerance before they drop into the bags. Multi‑head weighers typically deliver ±0.1–0.5 g accuracy per dose, whereas basic VFFS lines with volumetric fillers are around ±1–2% of target weight. VFFS defines packaging speed, bag style, film width, and footprint, while the multi‑head weigher defines weight accuracy, number of heads (often 10–24), and product throughput.

How much does a snack packaging machine cost and what’s the typical ROI timeline?

Industrial snack packaging machines typically cost about USD $20,000–$65,000 per line. Entry-level automatic VFFS with linear/multihead weighers are roughly $20k–$25k, while higher‑speed or rotary/MAP tray systems range from $45k–$65k. With typical snack margins and line speeds, the payback (ROI) period is often about 12–36 months, with well-optimized automatic systems recouping investment near the 18–24 month mark under continuous production.

Can I use the same machine for both chips and nuts, or do I need separate equipment?

Yes, the same vertical form fill seal (VFFS) packaging machine with a multi-head weigher can be used for both chips and nuts. Models like DS-420A and DS-420AZ are explicitly specified for potato chips, biscuits, pistachios, peanuts, and other fragile granular snacks without requiring separate equipment.